Hailong Group Precision Casting for Machine Tool

Large metal machine tool base bed frame sand casting Brief:1. Material: Gray Iron or Ductile Iron;2. Surface treatment: ;

Basic Info

| Model NO. | HLC |

| Surface Treatment | Shot Blasting, Machining, Painting |

| Surface Roughness | Ra0.1 |

| Standard | JIS |

| Certification | RoHS, ISO 9001:2000 |

| Product Name | Large Metal Machine Tool Base Bed Frame Sand Cast |

| Material of The Lathe Base | Ht200-300 (Gg20-30, FC200-300, ASTM No.30-45 |

| MOQ | 1set |

| Lathe Base Surface Treatment | Shot Blasting, Machining, and Painting |

| Application of The Lathe Casting | Machine Body (Bed, Base, Stands, Saddle, etc) |

| Weight | 17kg to 18000kg Per Set |

| Color | Nature Color, or Painting |

| Heat Treatment | Available |

| Casting Service | OEM According to Drawing or Sample |

| Transport Package | Wooden |

| Specification | Custom milling machine casting |

| Trademark | OEM |

| Origin | Qingdao, China |

| HS Code | 7325101000 |

| Production Capacity | 1000 to 1200tons Per Month |

Product Description

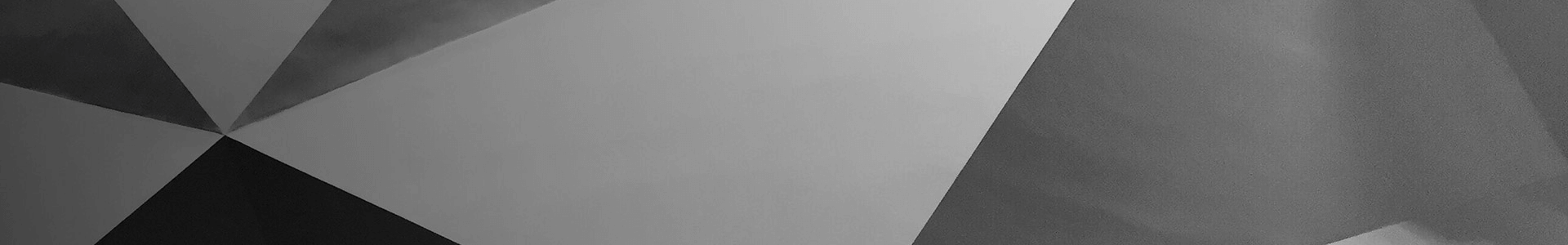

Large metal machine tool base bed frame sand casting

Brief:1. Material: Gray Iron or Ductile Iron;2. Surface treatment: Shot blast, painting; Heat treatment is optional;3. Custom according to your drawing, specification or samples;

Hailong Group is located in Qingdao, started in 1955. Large manufacturer for iron casting service. Mainly forCNC machine tools casting, auto stamping molds castings. It includes casting machine base,casting saddle,casting workplate, casting column (stands) .

Specifications of casting

| Product | Large metal machine tool base bed frame sand casting |

| Casting process | Resin sand casting, lost foam casting, steel mold casting, wood mold casting |

| Certifications | ISO9001: 2008 , V16949 |

| Iron cast applications | Machine tool body ( machine tool beds, work tables, bases, beams and columns) |

| Iron cast specification | 1.Material: gray iron HT200-300 (GG20-30, FC200-300, ASTM No.30-45).2.Standard: ASTM\DIN\BS\JIS\GB\AS.3.Surface finish: shot blasting, painting, machining,etc.4.Weight: 30kg to 18Tons per piece |

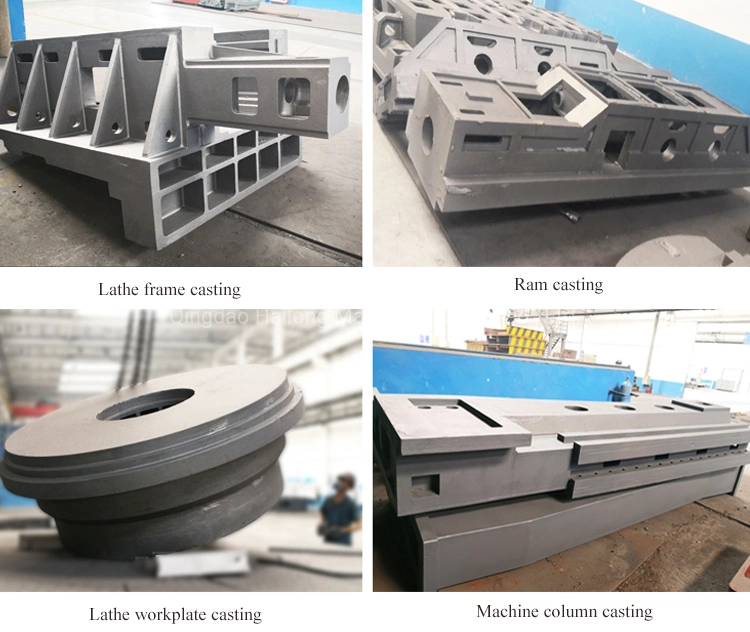

| Production facility | 1.Casting facility: Electric furnace(From Amrica10T*1, 2T*1);heat treatment house,shot blasting room,lost foam production line;2.Machining facility: CNC, oring machine, milling machine, vertical lathe,etc. |

| Testing facility | Sectrometer, tensile test machine, hardness test machine,metallographic microscope. |

| Cast Iron service | OEM according to customer's drawing or sample |

Workshop for machine tool castings

Super quality made by advanced casting machines, and complete testing equipment for well control the iron castingparts quality.

Machined treatment is available.

From raw material to finished casting products, well quality control.

FAQ:

1

Q: What are the main materials of your products? A: Gray iron and ductile iron;2.

Q: What is your MOQ? A: 1set 3.

Q: What is your main equipment? A: Our casting equipment is brought from America. Vertical and horizontal machining centers and CNC Gantry machining center mainly from Japan.

4.

Q: What's your advantages? A: 1) Large group company, with more than 60years experience; 2) Our lost foam casting well meet your small quantity or sample custom requirement; 3) About 1000-2000tons/month capacity, well meet your large quantity casting requirement; 4) With high level raw material for the casting parts production.

Hailong Machinery Group your best Choice!

You may also like

Send inquiry

Send now